Water loses its pressure as it flows through building pipes. Exacerbated by tankless systems, pressure drop can be a challenging design caveat.

Mechanical Engineer | Sales Engineering and Education Manager at Intellihot

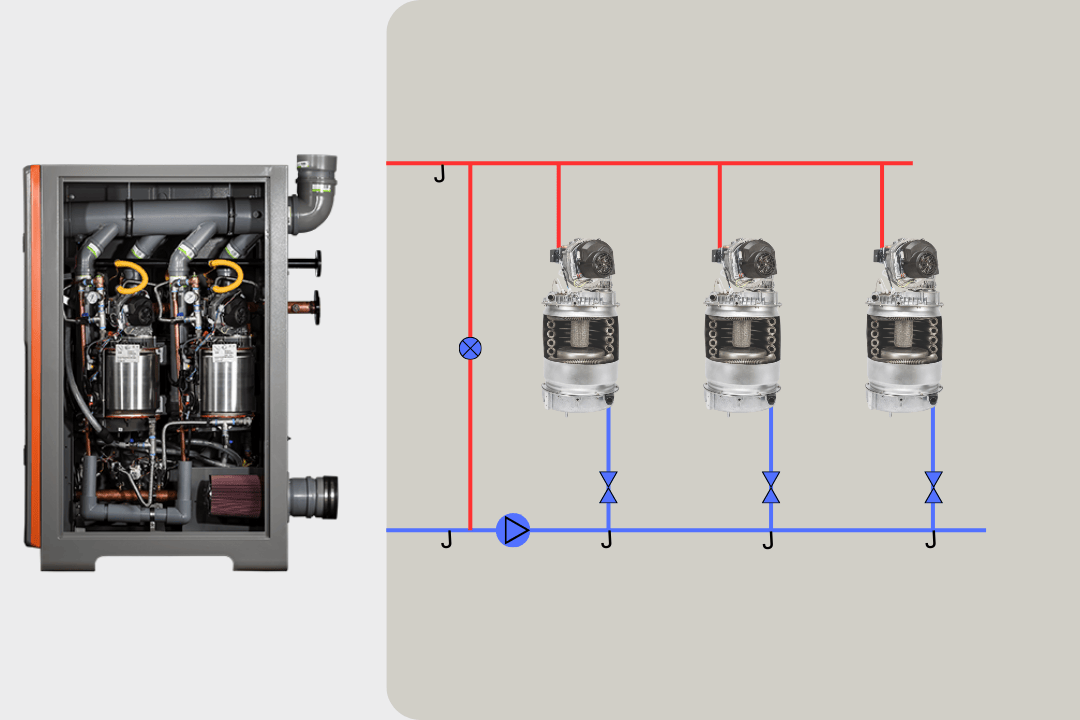

Intellihot’s patented low loss header design

As water flows through restrictions in pipe, its loses energy due to friction. A typical tankless system has very tight passageways inside the heat exchanger. When water is forced through these tight passageways, the pressure in the building system decreases. This is commonly referred to as pressure drop.

For large properties, this means:

Intellihot has a patented low-loss header design. A low-loss header is a concept that’s applied primarily in the hydronics world. It is a method upon which hydraulic separation is used to mitigate pressure drop.

In a low-loss header, you do not force all of your flow rate through your restriction. In our system, water is coming in through the cold water supply at the bottom and being forced by a pump through the heat exchangers. As flow goes through the heat exchangers, it does drop a little bit of pressure, and then it comes out and gets delivered to the fixtures.

Now, what happens when flow starts to increase is that a small amount of flow starts to go through a bypass line. This is why the bypass line exists inside our units. At a certain point, the pump pushing flow rate through the heat exchangers is no longer the path of least resistance, so water starts to flow through the bypass.

This is why we have manifold inlet and manifold outlet temperature sensors. The temperature sensors are going to correct the outlet temperature for the small amount of flow that’s bypassing through the bypass line.

Say you’ve got your unit set to 140 degrees. The minute flow starts bypassing through the bypass line, the heat exchangers start to fire a little bit above 140 degrees. Now, I’m delivering water from my heat exchangers at 150-160, and that’s mixing with the water at the outlet, which is providing the temperature that’s desired to the fixtures. The sensors are able to sense and correct for temperature changes 20 times in a single second, ensuring accurate fixture temperature.

Why are we designing the unit this way?

Well, when I have a 50 GPM event occur across my water heater, rather than trying to force 50 GPM through our three heat exchangers, which we won’t be able to do, we allow some of that flow to go through the bypass.

This is a core tenant of our modular design because it allows multiple heat exchangers to work together in order to meet the capacity of the system without dropping all of the pressure that you would if you had to force that flow through the heat exchangers, like typical tankless systems.

Lunch & Learn for Engineers

Robbie Svidron,

Sales Engineering & Education Manager

B.S. in Mechanical Engineering

*We will send a DoorDash gift card for virtual meetings.

2900 W Main St.,

Galesburg, IL 61401

General: 1-877-835-1705

Product Support : 1-866-692-6791

Product Support Standard Hours: 8 AM to 5 PM CST

Product Support After Hours: 5 PM to 10 PM CST